Manufacturing matters to Minnesota’s economy

By Sean O'Neil

Senior Director of Economic Development and Research

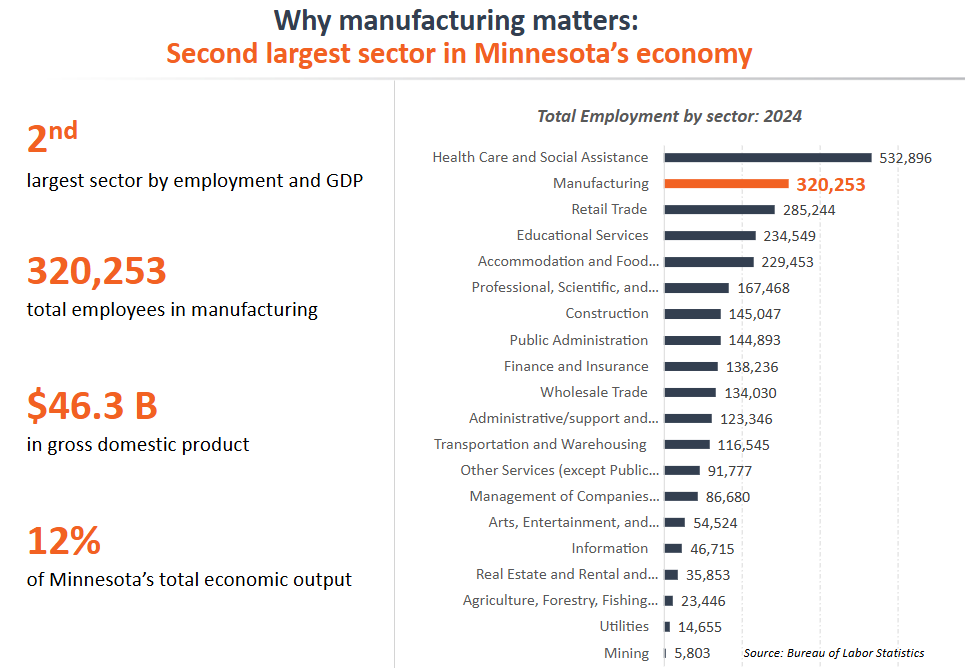

The success of Minnesota’s economy is inextricably linked to the vitality and growth of its manufacturing sector. Manufacturing is Minnesota’s second largest sector, making up 12% of the state’s total economy. Many of Minnesota’s most recognizable companies and nationally competitive industry clusters have emerged from the state’s highly diverse manufacturing sector.

It is not just the size of Minnesota’s manufacturing sector that makes it foundational to the state’s economy.

- It is one of the few sectors that is critical to each region in the state, rather than being primarily concentrated in the Twin Cities metro or Greater Minnesota.

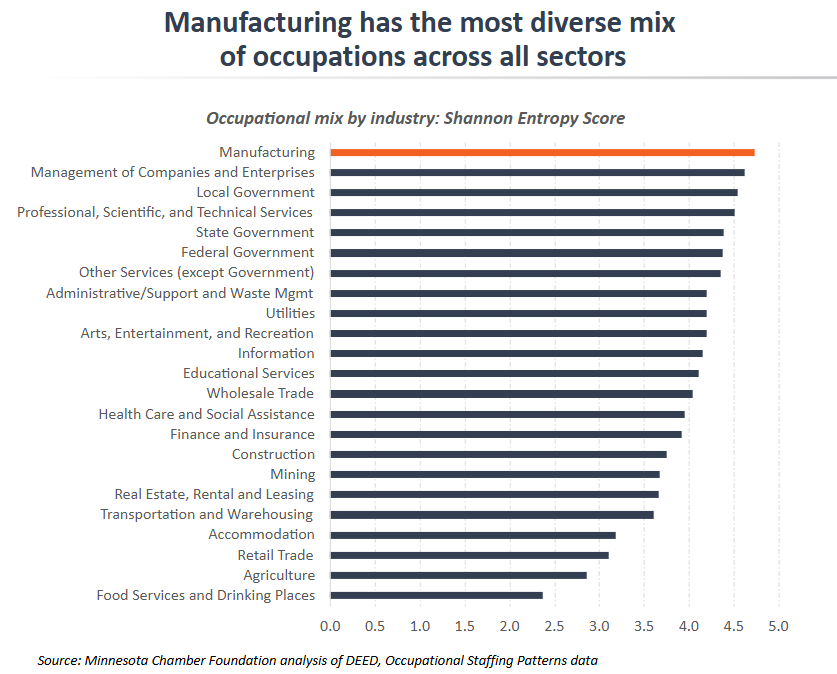

- Manufacturing provides above-average wage jobs to workers with a wide range of skills and education and has the highest occupational diversity of any sector.

- Manufacturing has an outsized impact because of its tradability and its ripple effect throughout the local economy. National data show that manufacturing has the highest multiplier effect of any sector, with every $1 spent on manufacturing leading to $2.78 spent on the rest of the economy.

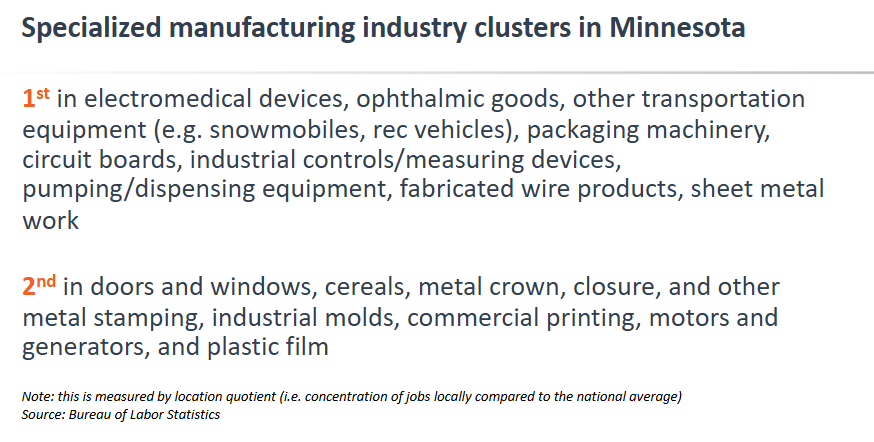

- Minnesota is a national hub for manufacturing, with leading industry clusters across a variety of subsectors, such as medical devices, food products, doors and windows, machinery, recreational vehicles, industrial controls, sheet metal and more.

These attributes make manufacturing a fundamental driver of Minnesota’s economy and its future outlook. The state cannot reach its full potential without a thriving manufacturing sector.

This article is the first in a series that will break down what manufacturing means to Minnesota. A series of five articles will assess:

- The role of manufacturing in Minnesota’s economy

- Minnesota’s manufacturing performance over time and compared to other states

- The impacts of rising operational costs and regulatory complexity

- Impacts of workforce availability on Minnesota’s manufacturing performance

- Why enhancing productivity and innovation is the secret ingredient to the future growth and vitality of the state’s manufacturing sector

Reasons why manufacturing matters in Minnesota

Manufacturing is Minnesota’s second largest sector, making up 12% of the state’s total economy. Manufacturing is the second-largest sector in Minnesota by both employment and GDP output. With over 320,000 workers, manufacturing supports about one in every eight jobs in the state. In 2024, the sector produced $46.3 billion in gross domestic product – about 12% of Minnesota’s total economic output. If Minnesota’s manufacturing sector were a state economy, it would be larger than the entire economies of Wyoming and Vermont.

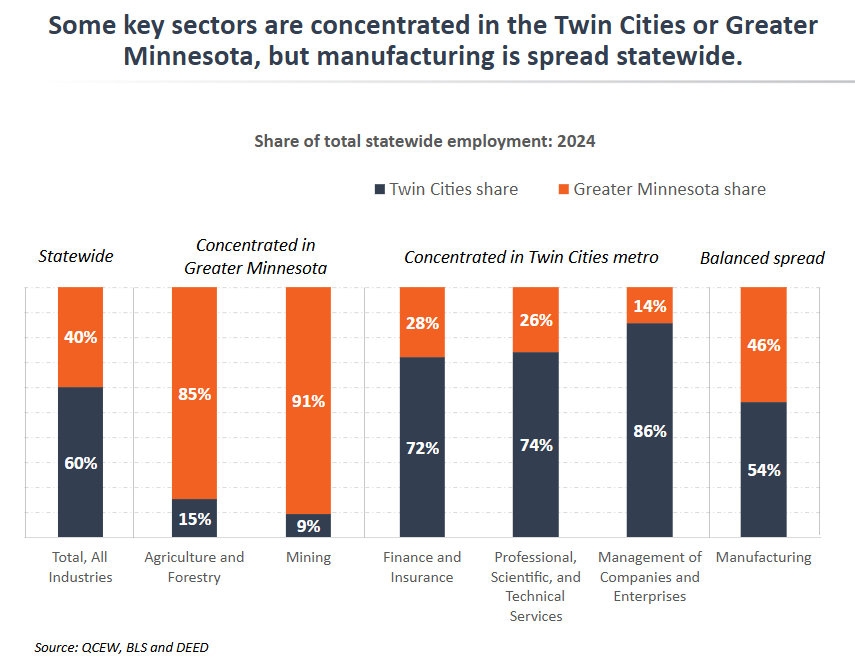

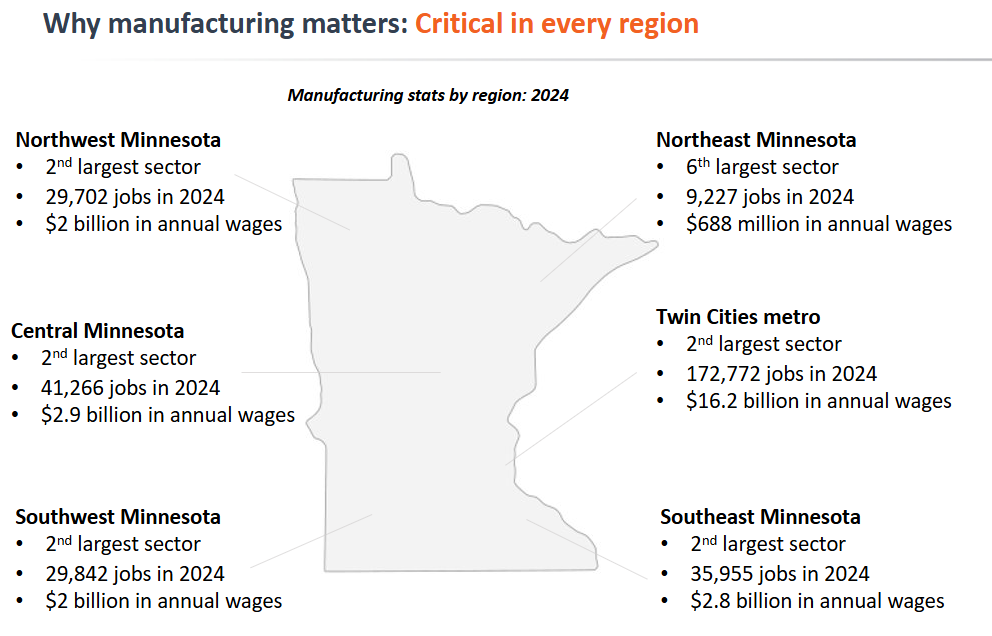

Manufacturing is critical to every regional economy in Minnesota. Manufacturing jobs are broadly distributed across Minnesota. About 54% of manufacturing jobs are in the Twin Cities metro, while 46% are in Greater Minnesota. Other key sectors are more geographically concentrated. For example, over 85% of agriculture and mining jobs are located outside the metro, while upwards of 80% of finance and insurance, professional services and corporate headquarters jobs are concentrated within the Twin Cities metro.

Manufacturing ranks as the second-largest employment sector in every Minnesota region except for the northeast region of the state, where it still ranks sixth by jobs – but third by total wages paid. This demonstrates the disproportionate impact of the sector, even in areas where it isn’t dominant in job count. Its presence in every corner of Minnesota makes it essential to the economic health and performance of communities around the state.

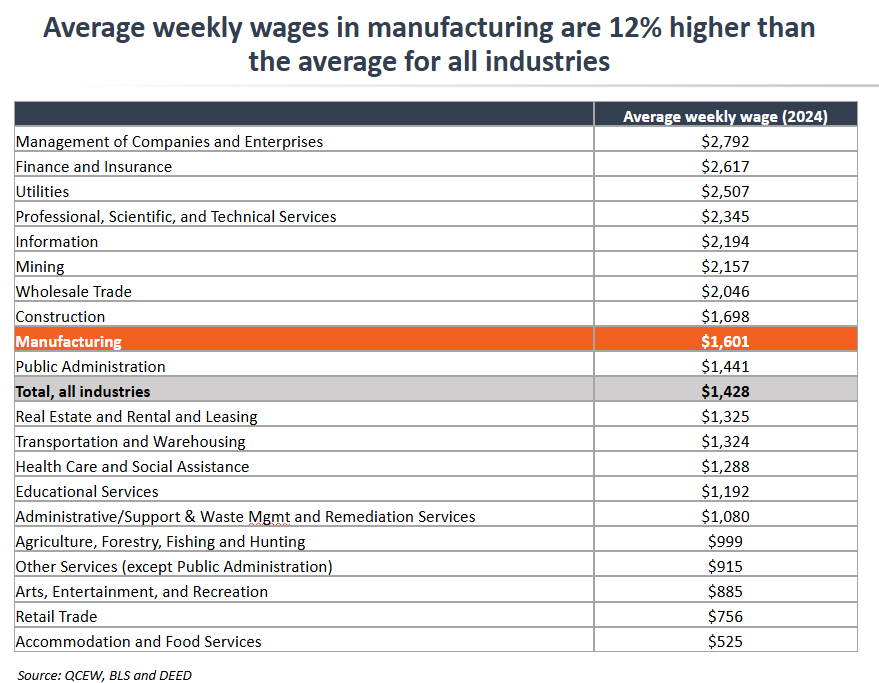

Manufacturing jobs provide above-average wages to workers with a wide range of skills and education. Manufacturing jobs are often sought after by communities and economic developers because they offer above-average wages and provide opportunities for workers with a wide range of education and skill levels. In 2024, the average annual wage for manufacturing jobs in Minnesota was $83,000 – 12% higher than the average across all industries.

Minnesota’s manufacturing sector also employs workers in 416 different occupational categories, giving it the most diverse occupational mix of any industry. This means people with varied training and backgrounds can find meaningful opportunities within manufacturing. For example, a single facility might employ entry-level production workers with only a high school diploma, machinists and maintenance technicians with a two-year technical degree, business operations staff with a bachelor’s, and engineers and scientists with advanced degrees. These roles require a range of technical, mechanical, analytical, and interpersonal skillsets that reflect the diversity of interests and capabilities in any given community.

Not all industries offer this kind of broad occupational and skill range. A financial services firm, for example, may have few or no employees without a bachelor’s degree, while a local restaurant may employ very few workers with more than a high school education. This is not a negative mark on those industries – it simply highlights manufacturing’s distinct role in the economic makeup of a community or region, with its wide occupational mix being one of the key benefits it brings.

Manufacturing has an outsized impact because of its tradability and ability to boost spending in the local economy. Manufacturing is considered a tradable sector, where goods can be sold and delivered to customers in markets outside the regions where they are produced. An equipment manufacturer can sell products in other states or countries, but a local dentist cannot easily sell services to customers outside of the immediate area. Though all sectors play an important economic role, economists identify tradable sectors as having an outsized impact on local economic growth, as they draw new money into the region from markets elsewhere rather than circulating it within a community.

Further, tradable sectors have ripple effects, as they spend money in the local supply chain and induce demand for other local services. The Chicago Federal Reserve explains: “Manufacturing has long-been recognized as an important driver of local employment growth because it produces ‘traded’ goods—i.e., goods that are sold nationally or internationally rather than only locally… This means that new employment in traded goods industries can have a “multiplier” effect because it also tends to lead to new employment in local industries. Thus, in theory, growth in a region’s traded goods industries should be a good predictor of growth in overall employment in a region.”

Research on the national manufacturing sector consistently shows it among the highest multiplier effects of any sector. The National Association of Manufacturers shows that every $1 spent in manufacturing generates a total impact of $2.64 to the overall economy. Additionally, each manufacturing job created can lead to 4.8 jobs created in the overall U.S. economy through indirect and induced impacts. (Source: NAM calculations using 2023 IMPLAN data) This economic modelling matches anecdotal evidence from outreach to businesses and communities around the state. Business retention and expansion visits conducted through the Grow Minnesota! program often reveal that local manufacturers make up the leading customer segment for community banks, construction firms, professional services, utilities and other industries.

Similarly, manufacturing drives Minnesota’s international exports. In 2024, state manufacturing exports were valued at $25 billion, making up 93% of total goods exports and nearly two-thirds of all goods and services exports. Manufacturers sold their products to over 200 countries. Top export destinations included Canada, Mexico and China, and key products included medical devices, industrial machinery and electrical equipment. These exports highlight the global competitiveness of the state’s manufacturing industry, as its companies and industry clusters compete and win in the global economy.

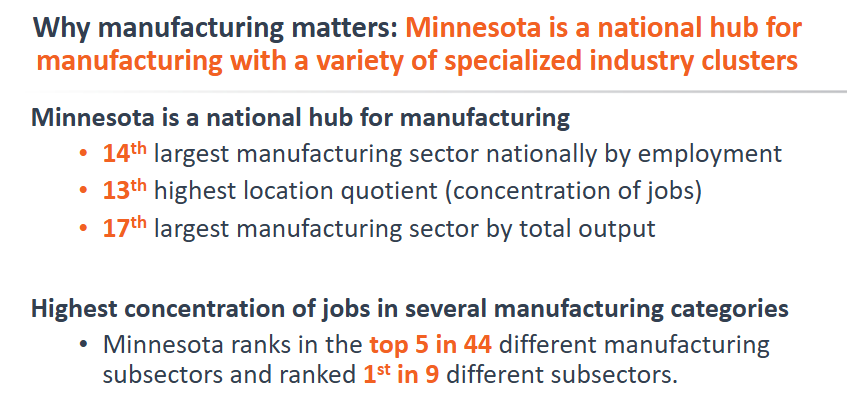

- Minnesota is a national hub for manufacturing, with leading industry clusters across a variety of manufacturing subsectors. Minnesota is a national leader in manufacturing by multiple metrics. While Minnesota has the 22nd largest population, it ranks 14th in total manufacturing jobs, 13th in job concentration (location quotient), and 17th in manufacturing GDP output among all states.

Minnesota has developed numerous nation-leading industry clusters that are part of the broader manufacturing sector. The state ranks in the top five nationally in 44 distinct manufacturing subsectors and is #1 or #2 in sixteen subsectors – including medical devices, recreational transportation equipment, packaging machinery, printed circuit boards, industrial controls, pumping systems, sheet metal products, breakfast cereals, commercial printing, doors and windows and more. These are areas of competitive advantage that Minnesota does better than anyone else. They represent important industry strengths to leverage and build on for future growth.

Minnesota Chamber resources for manufacturers:

The Minnesota Chamber of Commerce and Chamber Foundation are committed to supporting manufacturers around the state. Below are some of the resources available to manufacturing businesses.

- Manufacturers Council – the Minnesota Chamber of Commerce also serves as the state manufacturing association. The Manufacturers Council provides an exclusive opportunity for manufacturing members to share best practices, advocate on behalf of key policy issues and join together to advance pro-growth strategies for manufacturers in Minnesota.

- ChamberHealth – through Minnesota Chamber Business Services, an association health plan specifically for manufacturers is available through ChamberHealth.

- Free one-on-one assistance from Grow Minnesota! – Grow Minnesota! is the state’s leading business retention program, providing free, customized assistance to manufacturers and businesses statewide on strategies to grow their companies, as well as problem solving to remove barriers.

- Online certificate of origin processing through essCert – the Chamber offers a streamlined certificate of origin processing system for quick and efficient approvals.

- Sustainability solutions and savings through Energy Smart and Waste Wise – the Minnesota Chamber Sustainability program provides cost saving consulting and recommendations for on both energy and solid waste. This innovative program has saved businesses millions of dollars throughout its history.

- Free resource guides on business funding, exporting and workforce – Grow Minnesota! has easy-to-navigate guides to help businesses access capital, find new markets and identify workforce partnerships in their communities.

Need more assistance?

The Grow Minnesota! team at the Minnesota Chamber of Commerce can provide additional assistance to help your business access the above resources.

Contact growminnesota@mnchamber.com for more assistance.